Fabricación de puertas de madera de alta calidad con seis máquinas de perforación NC máquina de grabado NC 1325 máquina de grabado de madera ATC máquina de grabado NC

six sided cnc drill machine good quality wood door making cnc router 1325 wood engraver atc cnc router machine

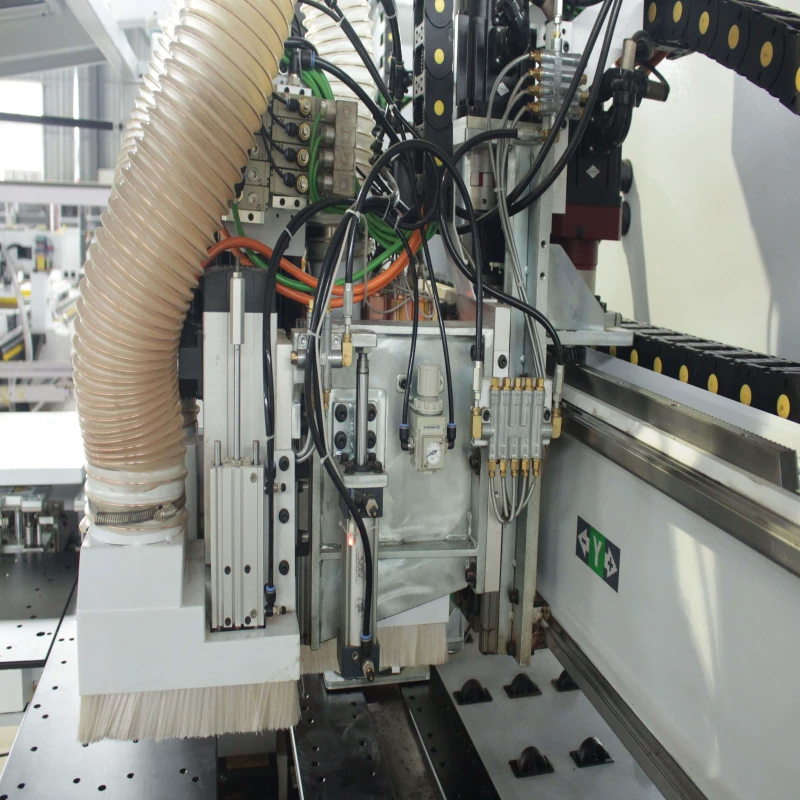

Jinan M-shine(M-PD-612D)“Six sided drilling machine ”Product Details

Application features: Double-drilling six-sided CNC drilling center, double-drilling package synchronously processes symmetrical hole positions, and the efficiency is doubled. It can be operated by a single person for ordinary workers, with a small workload, and can be directly connected with a variety of order dismantling software. It is mainly used for vertical and horizontal drilling of various artificial boards (hinge holes, through holes, semi-through holes, etc.)

1. The system recognizes the processing information by scanning the code, which is intelligent and efficient.

2. Computer operation, CAD drawing, CAM import, can directly import DXF, mpr, XML and other open data formats, easy to operate.

3. Using double gripper long guide rail, the maximum speed of grasping material can reach 130m/min, intelligent detection of hole position information can effectively avoid the drilling position, and reduce the time of changing hands during the drilling process. The stroke of the gripper is more than 5.5 meters, the large plate can be grasped and processed at one time, and the drilling processing time of the large side plate of the wardrobe is greatly shortened.

4. Equipped with an air flotation worktable and an air flotation platen. During the processing, an air layer is formed on the upper and lower surfaces of the plate, which improves the conveying efficiency of the plate and avoids scratching the plate; the platen drilling is completed at the same time to ensure drilling accuracy and efficiency; The installation position of the drill bag is unique, which avoids the edge of the hole caused by the floating of the plate during drilling, and the deviation of the hole position; and effectively prevents the dust accumulation of the drill bag from causing the bit to be stuck and affecting production.

5. The processing mode can be selected according to the production output and production process. In the forward and backward mode, the next plate can be processed after the plate is processed. The whole process is smooth and the standby time is short. The forward and backward mode can be connected to the production line. The comprehensive drilling reaches the level of the imported dual-station PTP drilling processing center; forward The front-out mode is mainly used for processing double-sided vertical drilling.

About us Our Partners Visit Our Factory:

M-Shine Technology Co., Ltd is the manufacturer which is specialized in CNC laser machinery. The products include laser engraving machines, laser cutting machines, laser marking machines, plasma cutting machines, cutting plotters, etc. The machinery are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.

We adhere to the Market-Oriented business principles, and implements the business philosophy of "Quality First and Customer First". Customized orders can be accepted so as to provide right products according to customers’ requirements. We pursue excellence and continuous improvement, and try our best to offer excellent-quality products with favorable prices and perfect services to customers.

Dedicated to strict quality control and perfect after-sales service, our products have been exported to more than 30 countries and regions. We are glad to be good friends and partners with you. Choose M-Shine, Shine your business!

FAQ.Jinan m-shine Brand CNC Panel Saw, providing various size and models. With 13 years experience , we accpet ODM and OEM according to requirements. Besides, we can suggest the suitable woodworking production line based on customer's factory and personnel situation.

Q1: This is the first time I buy the machine, is it easy to operate?

We can provide the operation manual or video for guiding. If it is hard for you learning, we can also help you by "Team viewer"online, with telephone or Skype explain.

Q2: How to choose a suitable machine?

You can tell us the working piece material, size, and the request of machine function. We can recommend the most suitable machine according to our experience.

Q3 :How can I trust your company and your products?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. The testing video and pictures will be available before delivery.

Q4.If machine have any problem after I ordered it, what could I do?

Free parts send to you in machine warranty period if machine have any problem. Free after-sales service life for machine, please feel free contact us if your machine have any problem. We will give you 24hours service from phone and skype.

Q5. Can I visit your factory?

Yes! We greatly welcome customers to visit our factory!

Q6. What's your date of delivery?

For standard machine, about 15 working days; For customized machine, about 20 working day.

Q7.MOQ?

Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

Jinan M-Shine Technology Co. , Ltd.

Address: 3-1405 Room, Dongdu International Plaza, Industrial North Road, Licheng District, Jinan City, Shandong, China

Factory Address: 800 meters north of the intersection of Airport Road and Wenliang Road, Licheng District, Jinan City

Mob:+8618766144006(stone) Mob:+8615990994941(leo li)

web:www.m-shine.com

https://mshinetech.en.alibaba.com

Email:info@m-shine.com leoli@m-shine.com

Tenemos más categorías para usted. Si no puede encontrar los productos que desea anteriormente, solo rellene el formulario y díganos qué productos desea importar de China.